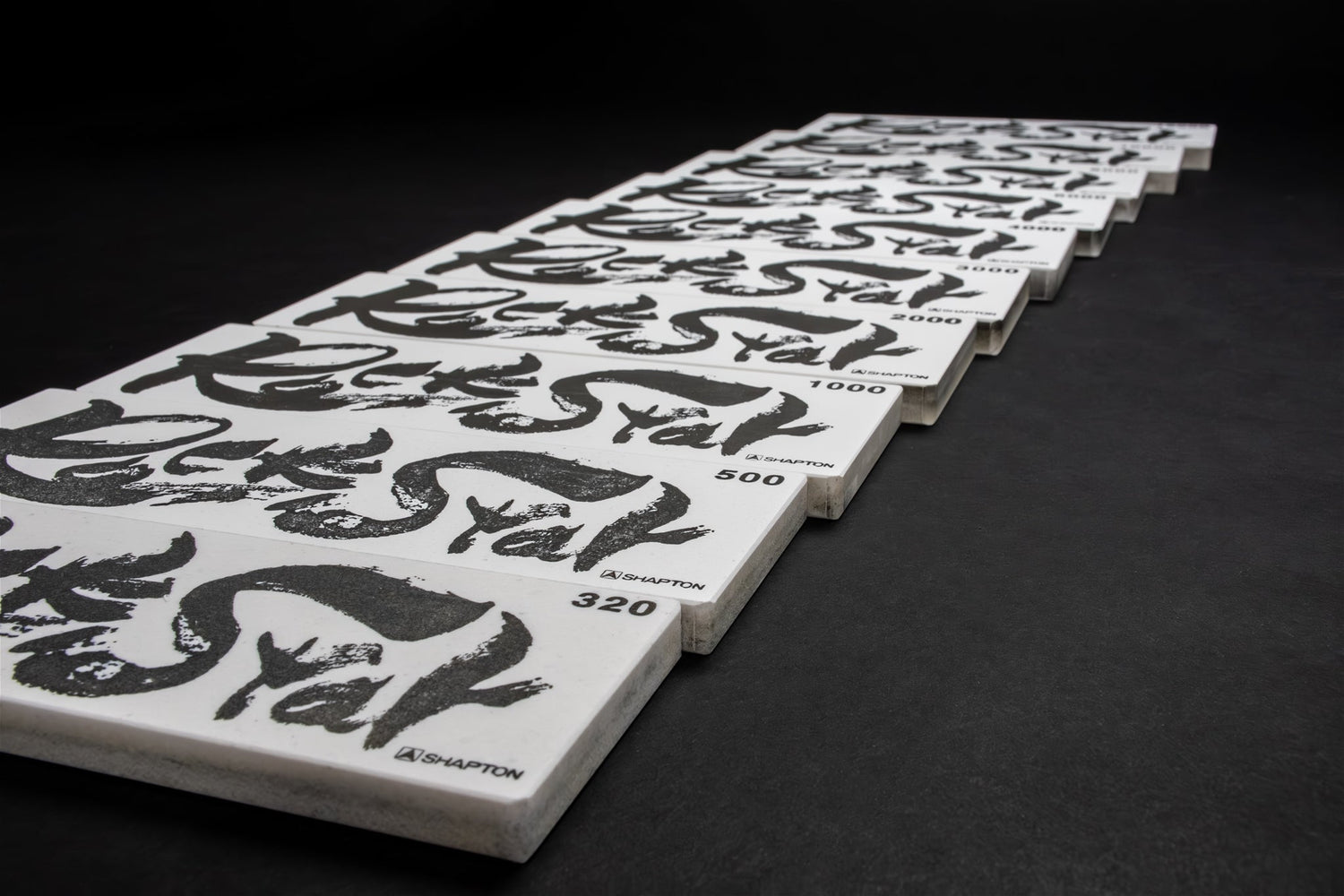

Guide to stone granulations

In the following text, we will explain in detail how to choose the best sharpening stone according to your needs and the results you want to achieve.

The final goal of using a stone is certainly a sharp knife, but there are different types on the market and in our offer, each of which has a specific purpose and the reason why it is the best for achieving a certain goal. Since the topic of sharpening stones is a little more extensive, we will start right away and directly.

The first question that almost automatically arises: why are there so many different granulations and how do I know which is the best for me?

The granulation of the stone tells us how coarse or fine it is. Sharpening stones are made from #140 grit, which is an extremely coarse grit, and go all the way up to the rare #30000 grit, which is extremely fine.

In short:

- Everything from #140 to #800 falls under rough stones.

- #1000 to #3000 is considered medium fine.

- Anything over #3000 is considered an extremely fine polishing stone .

Now that we know what each grit represents, the question arises: what grit is needed to sharpen your particular knife?

The answer to this question will depend on two factors.

The condition of your knife

- If your knife is damaged, has a broken point or chipped blade, you need an extra coarse stone.

- If you want to reprofile or thin the blade, you need it rough stone.

- If the knife is in good condition but completely dull, a coarser stone will save you more time sharpening, but you can also do this with a #1000 medium-fine stone.

- If your knife has lost its true sharpness, but is not completely dull, you should sharpen it on a medium-fine stone.

- If you sharpen your knife on a medium-fine stone, but you would like an even higher level of sharpness, then you also need an extremely fine stone.

- If you are used to working with an absolutely sharp knife and want to maintain its sharpness at the maximum level every day, extremely fine stones are a good choice for you.

The steel of your knife

- If you have a Japanese knife made of extremely hard steel (61+ HRC), you achieve its full potential on extremely fine stones.

- If you have a Japanese knife made of a slightly softer steel (59-61 HRC), you can achieve its full potential on a stone with a grain size of up to #3000.

- If you sharpen German knives made of higher quality steel (Zwilling, Wusthof, Gude), you achieve their full potential on stones between #1000 and #2000 grit.

- If you have European-made knives made of softer steel (Dick, Arcos, Sanelli), the maximum grit to which these knives should be sharpened is #1000.

- If you have knives made of extremely mild steel (most brands not mentioned above, Chinese knives and the like), it is preferable to sharpen them on coarser grits like #500 and #800. In the hobby variant, you can also get by with #1000 grit, with slightly more frequent sharpening.

The guidelines given above are an extremely good guide that can answer the question of which stone you need. Of course, there are isolated cases, such as hunting knives, where these rules will differ. We will cover this and many other topics gradually, so if you are one of those sharpening enthusiasts, be sure to follow our blogs!