Steel construction

Once we understand the manufacturing technology, we will easily recognize what type of construction or stacking of steel we see on a knife.

Quality steel is extremely expensive due to the demanding production process, that's why manufacturers came up with the idea of wrapping steel with other, cheaper steel in order to make a more acceptable product. At one point, the devil took the joke away, and today companies are almost competing to produce the "prettier" steel, that is, whose knives will have the prettier pattern. There are countless techniques for different damask patterns that produce extremely beautiful products. We'll break down a few of the most popular builds and highlight the benefits of each.

SOLID OR MONO STEEL

At their simplest, these are knives made from a single piece of steel. The knife has the same characteristics from start to finish and this technique is more present in European knife makers, but we can also often see it in Japanese commercial knives. If you own any " regular" knife, it is constructed this way. The advantage of these knives is the lower price, which is associated with a simpler manufacturing process compared to folded steels. The image below is a schematic cross-section of a knife that illustrates this case.

LAMINATE

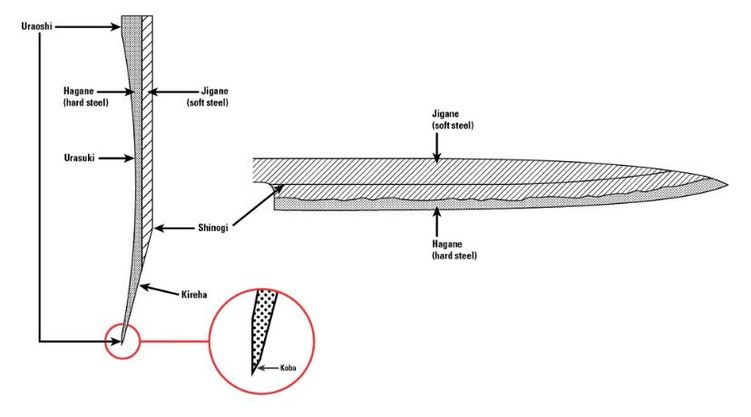

When we have a situation where two different steels are glued to each other in only 2 layers, we call such a construction a laminate. It can be seen in all Japanese traditional knives (Yanagiba, Deba, Usuba) and the harder steel on the diagram shown in black will always be exposed as the steel that actually provides the blade. You may wonder why a different type of steel is put in at all, why isn't the entire blade made of one type? The second steel, shown in white in the picture below, has different characteristics, such as flexibility and softness, which allows the smith to better manipulate the blade, making it easier to correct it if the steel becomes distorted during tempering and grinding or during improper use of the blade in further work. This technique is believed to have been inherited from the Japanese katana making system.

SAN MAI OR SANDWICH CONSTRUCTION

Three layers of steel, of which the one in the middle is always of better quality. We will often see this construction when the manufacturer tries to reduce the exposure of rusting steel to the external factor and thus save it from the oxidation process. Only a small part of the knife with the quality steel blade will be exposed, which drastically reduces the need for knife maintenance. Also, this construction is used when we have knives made of extremely expensive steels like SG2, R2 or VG10 in order to reduce the price of the product, and the user has the same effective blade as if it were made from one piece. In the diagram below, quality steel is marked in black, while the one on the side is always much cheaper. This in no way negatively affects performance, but rather gives the knife a higher level of resistance to both rust and breakage. We can also visually notice this technique on the knife in the form of lines a few millimeters behind the blade itself, on both sides of the knife.

DAMASCUS WITHOUT CENTER STEEL

A steel folding technique extremely popular for its aesthetic features, but which rarely has any real impact on how the knife cuts food. Coreless damascus refers to the overlapping of two or more types of steel where the overlapping steel forms both the blade and the body of the knife. The patterns on these knives become clearly visible because the steels usually differ in their nickel content. With different processing techniques, this difference is emphasized more or less, depending on the aesthetic effect that the manufacturer wants to create. Throughout history, carbon, i.e., rusting steel was used for this technique, however, it is now more often avoided because users, due to proper and regular maintenance, "erase" the patterns that were present on the knife and do not know how to restore them, and the blade loses its unique aesthetic element.

DAMASCUS WITH CENTRAL STEEL

Probably the most popular way of making knife steel today is stacking Damascus steel around a central, very high quality steel. Go back to the story of the San-mai construction and imagine that instead of ordinary, cheap steel, damascus was used. Make no mistake, this damascus is also made from lower quality steels, because as with the San-mai technique, it never presents a blade, but the range of possibilities for the appearance of the knives obtained with this technique is almost unlimited. More or less accentuated patterns, fog effect, wavy, round, zigzag patterns, even adding copper or silver to the damascus, all this makes the knives in this construction look enchanting and maintain top performance. The appearance of these knives can be influenced by so many factors that even the master's mood can be directly expressed. It is believed that just looking at perfectly crafted blades awakens a feeling of joy and excitement in a person. It is for these reasons that the prices can be very high, but hey, you are getting a knife that is not only perfectly sharp but also looks beautiful.